Across the food and beverage industry, there is little debate left about the long-term role of synthetic colorants.

Regulatory scrutiny continues to increase, major retailers are tightening ingredient standards, and consumer perception has shifted decisively toward cleaner, more transparent labels. For many brands, synthetic colors are no longer a defensible default, they are a liability waiting to surface.

Yet despite broad agreement on where the industry is headed, progress remains uneven. The challenge is not awareness or intent. It is execution.

Replacing a synthetic colorant with a natural alternative is rarely a straightforward, one-to-one substitution. Synthetic colors are engineered for consistency, intensity, and robustness across a wide range of processing and storage conditions.

Natural colorants, by contrast, are inherently more variable and system-dependent. Their performance is influenced by formulation chemistry, processing conditions, and packaging in ways that are often underestimated early in a project.

What appears simple at the ingredient list level quickly becomes complex at the product level.

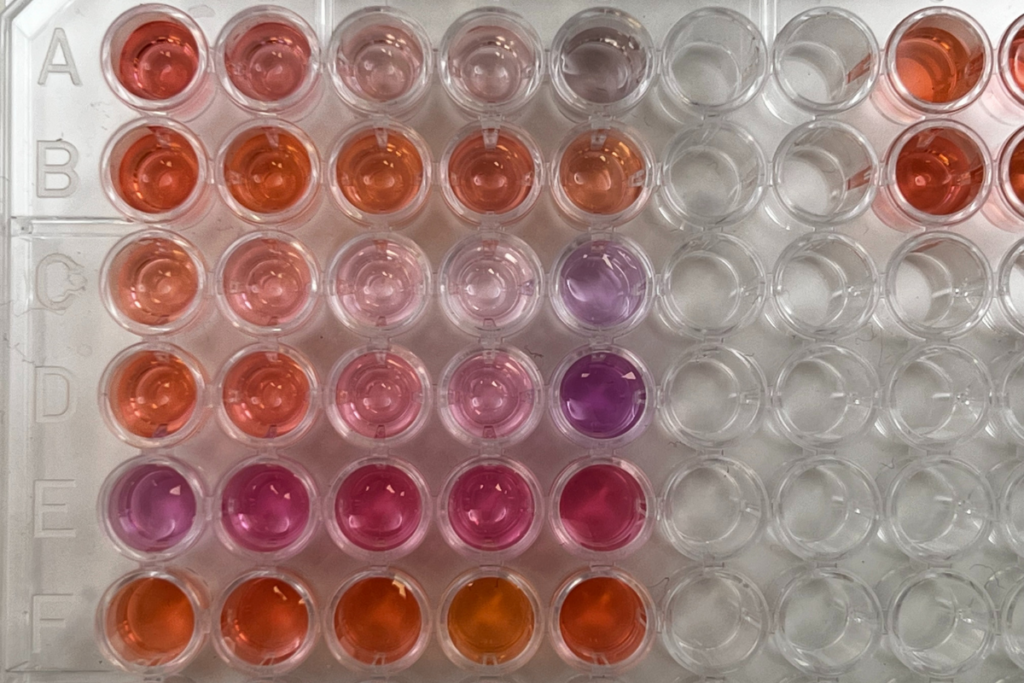

Behind every successful color replacement is a substantial body of work that often remains invisible to non-technical stakeholders. This includes iterative color matching to achieve target hue and intensity, stability testing under real-world conditions, and validation across shelf-life and distribution scenarios.

Heat treatment, pH, light exposure, oxidation, and interactions with other ingredients can all dramatically affect color performance. In many cases, process steps such as pasteurization, extrusion, frying, or retorting introduce additional stress that must be accounted for during development.

This hidden workload is where many reformulation efforts stall. Teams frequently underestimate the time, instrumentation, and experimental rigor required to move from a promising natural color candidate to a solution that performs reliably in market-ready products.

Visual checks or short-term trials may suggest early success, only for issues such as fading, browning, phase separation, or batch-to-batch variability to emerge later, often after scale-up or initial commercialization.

As a result, synthetic color replacement is less a single decision and more a structured technical process. Without adequate bandwidth, expertise, and objective validation, even well-intentioned initiatives can become prolonged, expensive, or inconclusive.

The industry consensus is clear: synthetic colors are declining. The unresolved question is not whether to replace them, but how to execute the transition effectively within real-world constraints.

If natural color reformulation or synthetic dye replacement is on your roadmap—but execution is the bottleneck—VK Business Solutions is preparing to support these projects. Follow us or contact us to learn more about our food color stability testing and screening services.